ProductProduct Center

YongJia DuoJia Hydraulic Equipment Co., LTD

Phone:+86-18177309287

Email:djvalvetestbench@126.com

Add.:Sanqiao Industrial Zone,Yongjia Country , Wenzhou, ZheJiang Province ,China.

Contact:Mr. Kevin

DYFJ-A

DYFJ-A

|

Descripition: |

Hydraulic Valve Test Bench |

|

Model: |

DYFJ-A |

|

Testing Range: |

DN15-1000 |

|

Testing Medium: |

Water,Gas or Oil |

1. Summary

The hydraulic valve test bench of model DYFJ A is specially applied to test all kinds of flanged valves,such as gate valves, ball valves, globe valves, check valves etc. The test bench is effectively composed of four parts, that is, mechanical system, hydraulic system, electric system and testing medium circulating system. The entire process of the loading and clamping of the valve to be tested is completely controlled by electric components and hydraulic components. The testing medium can be water, gas or oil. And the maximum testing pressure of shell test with liquid (water) is 48Mpa. Test benches of this model are of the following features,such as rational and compact in configuration, flawless in function, steady and reliable in performance,high in degree of automation, advanced in technics and so on.

What is important, the test benches of this model have no effect of external force upon the valve body,because the clamping jaw clamp directly on the flange of the valve. One side of the bench can be moved,thus the testing won′t be restricted by the structural length of the valve to be tested. When testing valves, clamp the flange on the both sides of the valve to be tested, pressurize to the necessary pressure of the medium′s intensity test and perform intensity test of the valve body, valve cover and middle flange. And the other side of the bench can be reversed by 90 degrees to perform leakage test and air tightness test. The testing methods of the test bench conform completely to the requirements of the following standards,GB/T13927-2008 ,JB/T9092-1999, API-598,API-6D&EN12266-1/2 standards.

“ Touch screen “ intelligent control system and printer system is optional ; Safety door device is optional .

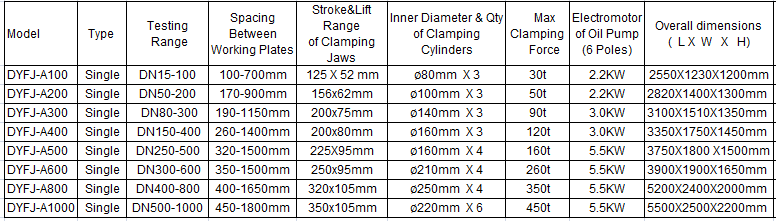

2. Technical Parameters .

3.Pressure Check List of Clamping Oil Cylinders .

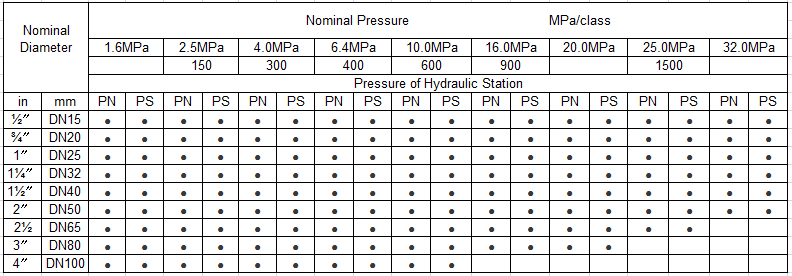

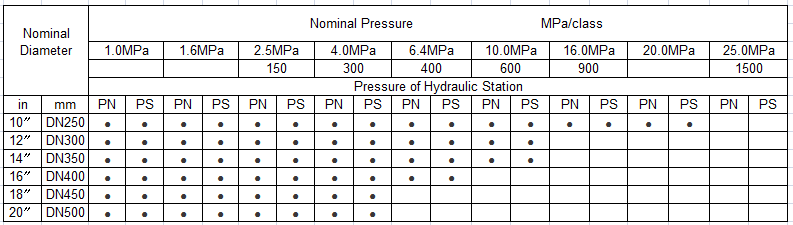

Molde :DYFJ-A100

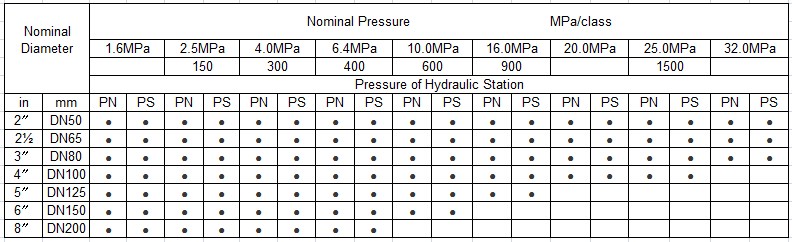

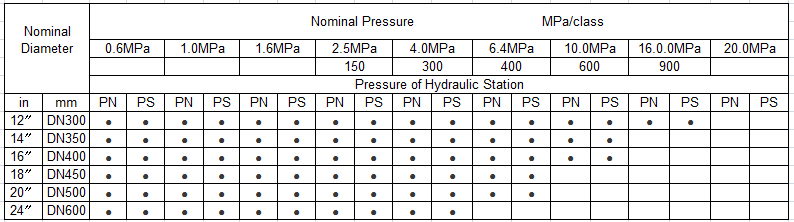

Moldel : DFFJ-A200

PN-denote the pressure of the oli cylinder when performing seat test ; PS – denotes the pressure of the oil cylinder when performing shell test .

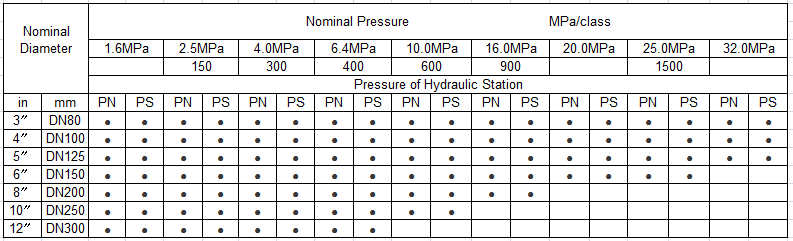

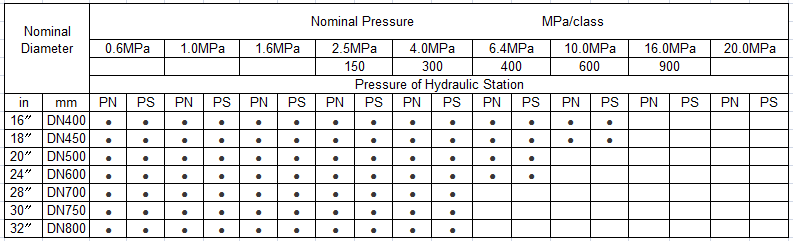

Model : DYFJ-A300

PN-denote the pressure of the oli cylinder when performing seat test ; PS – denotes the pressure of the oil cylinder when performing shell test .

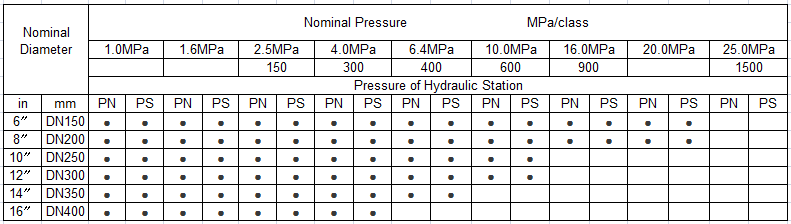

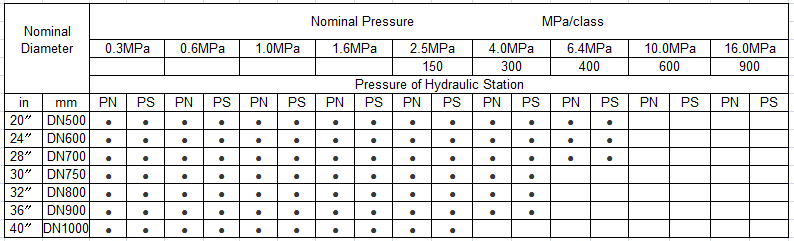

Model : DYFJ-A400

PN-denote the pressure of the oli cylinder when performing seat test ; PS – denotes the pressure of the oil cylinder when performing shell test .

Model :DYFJ-A500

PN-denote the pressure of the oli cylinder when performing seat test ; PS – denotes the pressure of the oil cylinder when performing shell test .

Model : DYFJ-A600

PN-denote the pressure of the oli cylinder when performing seat test ; PS – denotes the pressure of the oil cylinder when performing shell test .

Model : DYFJ-A800

PN-denote the pressure of the oli cylinder when performing seat test ; PS – denotes the pressure of the oil cylinder when performing shell test .

Model : DYFJ-A1000

PN-denote the pressure of the oli cylinder when performing seat test ; PS – denotes the pressure of the oil cylinder when performing shell test .

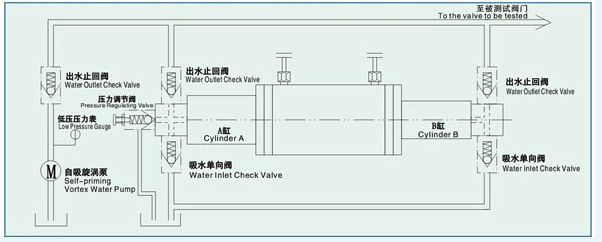

4. Schematic Drawings Of High&Low Pressure Water Pump.

Collection:YongJia DuoJia Hydraulic Equipment Co., LTD

Collection:YongJia DuoJia Hydraulic Equipment Co., LTD